Learn about Fabrics for Tents, Backpacks, Sleeping Bags, and Shells

Table of Contents

Fabrics Used for Backpacking Gear

Nylon and polyester are the most common fabrics used for backpacks, sleeping bags, shells, and tents.

Most mid- to high-end tents are made of nylon, while polyester is typically used for low-end tents.

Dyneema Composite Fabric (DCF), also called Cuben fiber, is used in some high-end tents and backpacks because of its strength, water resistance, and low weight. DFC consists of ultra-high-molecular-weight polyethylene (UHMWPE) coated on both sides with polyester. It’s extremely expensive.

Comparison of Polyester, Nylon, and Dyneema Composite Fabric (DCF)

| Cost | Weight | Strength | Abrasion Resistance | UV Resistance | Heat Resistance | Water Absorption | Stretchiness | |

|---|---|---|---|---|---|---|---|---|

| Highest | DCF | Polyester | DCF | Nylon | Polyester & DCF* | Polyester | Nylon | Nylon |

| Nylon | Nylon | Nylon | Nylon | Polyester | Polyester | |||

| Lowest | Polyester | DCF | Polyester | Polyester & DCF* | Nylon | DCF | DCF | DCF |

*Due to its polyester coating, DCF has abrasion resistance and UV resistance similar to those of polyester.

The above table compares fabrics that have the same denier and thread count (described below)

Ripstop Nylon

Ripstop nylon has strong reinforcement fibers interwoven at regular intervals in a crosshatch pattern. It’s highly resistant to tearing.

Fiber Weight and Denier

The heavier the fiber, the greater the strength and abrasion resistance. The most common unit for fiber weight is denier (D), the weight in grams of 9,000 meters of fiber.9,13

Water-resistant 10-20D ripstop nylon is the most common shell fabric. Backpacks should be made of at least 210D ripstop nylon to prevent abrasion. Most tents are made of 20-40D nylon. Utralight tents are typically made of 10-20D silicone-coated nylon. Many ultralight DCF tents are made of 5-10D DCF.

Thread Count

Thread count is the number of fiber threads per area and reflects how tightly the fabric is woven.10

Fabrics with high thread counts are warm, water-resistant, and down-proof—feathers and down quills aren’t lost through their pores.11 However, they aren’t very breathable.

Fabrics with low thread counts are breathable but not very warm, water-resistant, or down-proof. However, loss of feathers and down is usually not significant enough to affect insulation warmth.

Thread count is sometimes called “weave density” or “fabric density,” but these terms are ambiguous as they can also refer to fiber weight per unit area.

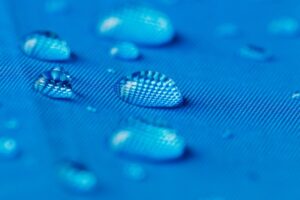

Fabric Waterproofing

Fabrics are typically waterproofed with one or more of the following coatings:

- Polyester urethane (PU)

- Silicone

- Polyether urethane (PE)

PU-coated fabrics are inexpensive and are commonly used in rain gear and tents. Although waterproof, they absorb water over time, making them stretchy, saggy, and susceptible to mildew. This is because PU is hydrophilic—it slowly bonds to water while preventing it from passing through.12

Silicone-coated fabrics have high tear strength, stretch resistance, and mold resistance, and they don’t absorb water.12 They are also expensive. Silicone-coated nylon, or silnylon, is typically used in mid- to high-end tents.

PE is rarely used, except in high-denier floors of heavy expedition tents.12

DCF is inherently waterproof and doesn’t need to be coated.

To learn about waterproofing for rain gear, see Learn about Rain Gear for Backpacking.

Pros and Cons of Waterproof Coatings

| Coating | Pros | Cons |

|---|---|---|

| PU | Highly waterproof High tear strength Affordable | Absorbs water over time Stretches when wet over time Susceptible to mold |

| PE | Doesn’t absorb water Doesn’t stretch when wet Highly resistant to mold | Low tear strength Uncommon More expensive than PU |

| Silicone | High tear strength Doesn’t absorb water Doesn’t stretch when wet Highly resistant to mold | More expensive than PU |