Beginner's Guide to Fabrics for Backpacking Gear

Table of Contents

Fibers, Fiber Weight, and Denier

Fibers are the basic building blocks of fabrics. The heavier the fiber, the greater the fabric’s strength and abrasion resistance. A common unit of fiber weight is the denier (D), defined as the weight in grams of 9,000 meters of fiber.1,2,3,4,5

Fabric Construction

Fibers can be knitted, woven, or non-woven.

Knitted Fabrics

Knitted fabrics are formed by interlooping yarns, which are long, continuous strands of twisted fibers. They’re usually used for clothes because they’re stretchy, comfortable, and breathable.

Woven Fabrics

Woven fabrics are formed by interlacing two sets of perpendicular yarns: the warp (vertical) and the weft (horizontal). This construction produces a strong, durable fabric with minimal stretch. Woven fabrics are used in backpacks, tents, tarps, outer shells, and pants.

There are three basic weave patterns:

- Plain

- Twill

- Satin

Comparison of Plain, Twill, and Satin Weaves

6

| Property | Comparison |

|---|---|

| Thickness | Satin > Twill > Plain |

| Softness | Satin > Twill > Plain |

| Smoothness | Satin > Twill > Plain |

| Density | Satin > Twill > Plain |

| Breathability | Plain > Twill > Satin |

| Durability | Plain = Twill > Satin |

| Stretch | Twill > Satin > Plain |

| Shrink resistance | Plain > Twill > Satin |

| Wrinkle Resistance | Twill > Satin > Plain |

| Ease of Care | Twill > Plain > Satin |

| Moisture wicking | Satin > Twill > Plain |

| Vapor diffusion | Satin > Twill > Plain |

| Evaporation | Satin > Twill > Plain |

| Affordability | Plain > Twill > Satin |

Non-woven Fabrics

Non-woven fabrics are made from fibers bonded together mechanically, thermally, or chemically without being knitted or woven. They’re used for insulation, waterproof–breathable membranes, and footwear insoles.

Fabric Density

Weave Density

Thread count is the number of horizontal and vertical threads per area.4,5,8,9,10 It’s sometimes expressed by the letter “T,” especially for polyester fabrics. “190T polyester” indicates a thread count of 190 threads per square inch.8,9

Weight per area is commonly measured in GSM (grams per square meter, g/m2)4

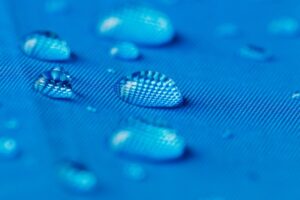

Fabrics with high weave density are smooth, soft, warm, durable, abrasion-resistant, and water-resistant. They’re also down-proof—feathers and down quills aren’t lost through their pores.12 However, they’re heavy and not very breathable.

Fabrics made of polyester or low-denier nylon fibers tend to have high weave densities to compensate for the weakness of the fibers. This makes the fabrics heavy.

A Common Misconception about "T"

It’s true that fiber weight is sometimes measured in tex instead of deniers.2 However, the “T” in “190T polyester” indicates thread count, not fiber weight.4,5,8,9 T does not stand for tex. I’ve confirmed this directly by email with a fabric manufacturer12. This misconception appears to have been spread by AI. (This is an example of why I don’t rely on AI when writing content for this website!)

Just remember that D indicates the weight per length of a fiber, while T indicates the number of threads per area of a fabric. D and T can’t be interconverted, because they’re independent of each other.

You don’t need to remember tex because it’s not commonly used for backpacking gear.

Knit Density

The density of knitted fabrics is called knit density, or knitting gauge—the number of stitches per area.

Fabrics with low knit density are loosely knitted—they have fewer stitches per inch. This structure allows for the use of thicker yarns, making the fabric thicker and warmer.

In contrast, fabrics with high knit density are tightly knitted, containing many stitches per inch. They require thinner yarns, making the fabric fine and lightweight.

Fabrics for Backpacks, Tents, Sleeping Bags, and Clothes

For details about fabrics for specific backpacking gear items, read the following articles:

Related Topics

References

12. Ninbo MH. Personal communication, August 19, 2025