Beginner's Guide to Fabrics for Backpacking Clothes

Table of Contents

Before Reading This Article ...

Summary

- Backpacking clothes should be made of merino wool or synthetic fibers because of their superior moisture management. Avoid other natural fibers, especially cotton.

- Merino wool resists odors better than synthetic fabric.

- Merino wool is slightly warmer when wet than synthetic fabric.

- Synthetic fabric is stronger and more abrasion-resistant than wool.

- If you buy synthetic fabric, make sure the fibers have been engineered for moisture management and breathability.

- Fabrics with high weave or knit densities are warmer and more durable, abrasion-resistant, water-resistant, and down-proof than fabrics with low densities.

- Fabrics with low weave or knit densities are more breathable than fabrics with high densities.

- Plain weaves are the most durable and breathable weave patterns.

Fabrics and Their Uses for Clothes

| Fabric | Appropriate Uses |

|---|---|

| Polyester | Base layers Mid layers (fleece, etc.) Shirts Rain gear Gloves Hats Insulation fill in jackets |

| Nylon | Rain gear Windbreakers, wind shirts Pants and shorts Shirts |

| Polypropylene | Base layers Sock liners Glove liners Hat liners |

| Spandex | Base Layers (usually blended with polyester or merino wool) Pants and shorts (usually blended with nylon) Shirts (usually blended with polyester) |

| Wool | Base layers Mid layers Socks Hats |

| Silk | Base layers Sock liners Glove liners Sleeping bag liners |

| Bamboo viscose | Base layers Socks Neck gaiters Hats |

| Cotton | Not suitable for backpacking clothes |

| Hemp | Not suitable for backpacking clothes |

Desirable Properties of Clothes Fabrics

When choosing fabrics for clothes, some important properties to consider are:

- Warmth (insulation performance)

- Breathability

- Moisture management (wicking and drying time)

- Odor resistance

- Tensile strength

- Tear strength

- Abrasion resistance

These properties are determined by the type, weight (density), diameter, shape, and surface roughness of the fibers as well as the weave or knit of the fabric.

Warmth (Insulation Performance)

The insulation performance of a fabric depends mostly on its weave pattern, weave density, and moisture management. The type of fiber has a negligible effect on insulation performance, except to the extent that it affects moisture management. 1

Breathability

Breathable fabrics allow air and moisture vapor to pass through gaps between their fibers to keep you cool and dry when you exercise.2

Water vapor diffuses from regions of higher humidity to regions of lower humidity. When you sweat, the higher humidity inside your clothes drives moisture vapor outward through the fabric. However, if the humidity outside the fabric exceeds that inside, this vapor pressure gradient disappears and water vapor diffusion is reduced or blocked.3

The breathability of a fabric is determined mostly by its air permeability, which is influenced by multiple factors, including:

- Fiber type (cotton, polyester, etc.)

- Fiber composition (blends)

- Fiber cross-sectional shape

- Fiber longitudinal shape (e.g., the natural crimping of wool fibers)

- Fiber smoothness (natural fibers are rough; synthetic fibers are smooth)

- Yarn thickness

- Yarn structure (e.g., one fiber vs multiple twisted fibers)

- Yarn twist

- Weave or knit pattern

- Weave or knit density

- Fabric thickness

- Fabric mechanical finish, especially hot calendaring (flattening of the fabric during the calendaring process)

- Fabric chemical finish (e.g., water-repellant coating)

- Fiber swelling in humidity (notably cotton)

When these factors are held constant, natural fibers exhibit higher air permeability than synthetic fibers because their irregular shapes and surface textures create gaps between them, which facilitates airflow. Cotton fibers are highly air-permeable when dry, but they swell when wet, closing the gaps between them and obstructing airflow.

- Hygroscopicity

- Fiber surface energy (boundary-layer effects)

- Electrostatic charge behavior

- Gas permeability through the fibers

- Water vapor diffusion through the fibers

Air Permeability of Various Non-engineered, Finish-free Fabrics

(at 0% humidity and identical fiber weights, fiber thicknesses, yarn thicknesses, yarn twists, weave densities, and fabric thicknesses) 4

| Non-engineered Fiber | Air Permeability at 0% Humidity |

|---|---|

| Hemp | Highest |

| Cotton | Moderate-High when dry |

| Wool | Moderate-High |

| Bamboo viscose | Moderate-High |

| Silk | Moderate |

| Polyester | Low |

| Nylon | Low |

| Polypropylene | Low |

Keep in mind that the synthetic fibers (polyester, nylon, polypropylene) in the above table are not engineered. In reality, many synthetic fibers are engineered for high breathability.

Also, the above table describes fibers, not knits or weaves. Many synthetic fabrics for outdoor clothing are breathable knits or weaves.

Weave Patterns and Breathability

5

Plain weaves are the most breathable. Satin Weaves are the least breathable.

Weave Density and Breathability

5

Lower weave densities exhibit better breathability.

Moisture Management

In addition to breathability, moisture management is an important function of fabrics for backpacking clothes. It involves three stages:2

- Wetting

- Wicking

- Evaporation

Stage 1: Wetting

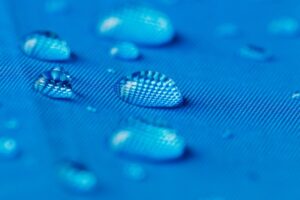

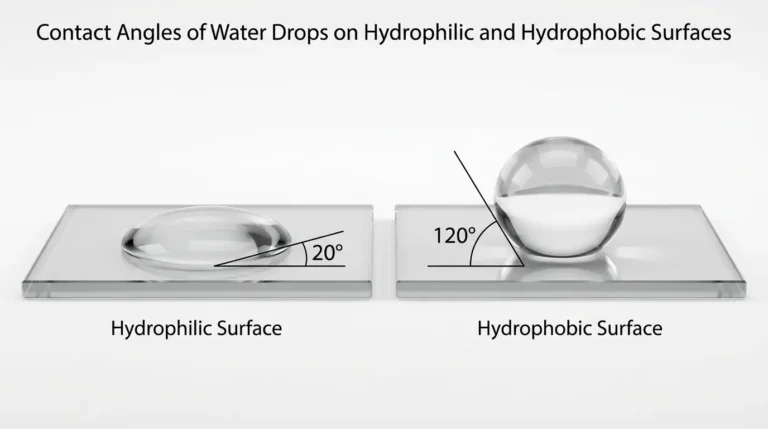

Fig. 1

Wetting is the ability of a liquid to maintain contact with a solid surface by displacing another substance (typically air). It is driven by intermolecular interactions between the liquid and the solid. A liquid exhibits high wettability when the adhesive forces between the liquid and the solid exceed the liquid’s internal cohesive forces. Simply put, wettability is how strongly a liquid adheres to a surface.6

Wettability is commonly measured by the contact angle (θC), defined as the angle formed between the liquid-air interface and the solid surface at their point of contact (Fig. 1). Contact angles less than 90° indicate high wettability, while contact angles greater than 90° indicate low wettability. Smaller contact angles correspond to greater spreading of the liquid across the solid surface. 7

The wettability of a material depends on its hydrophilicity or hydrophobicity.

Hydrophilic (water-attracting) surfaces contain polar or charged functional groups, such as hydroxyl (-OH) groups, which readily interact with water molecules, making the surface highly wettable.

Hydrophobic (water-repelling) surfaces are non-polar and lack charged groups, making them poorly wettable.

In the first stage of moisture management, sweat wets the fibers at the fabric’s inner surface. This process is governed by the wettability of the fibers

Stage 2: Wicking (Capillary Action)

Capillary action, commonly called wicking, is the physical phenomenon that draws water through a narrow tube. It’s caused by intermolecular forces between the liquid and its surrounding solid surfaces. The amount of force of the capillary action is called capillary pressure.2,8

In the second stage of moisture management, liquid moisture on the fabric’s inner surface is transported through the fabric’s structure by capillary action. The liquid moves through tiny gaps between individual fibers and yarns. Tighter yarn twists form narrower gaps between the fibers, generating higher capillary pressure and enabling faster transport over longer distances. Looser yarn twists form wider gaps, resulting in lower capillary pressure and slower, shorter transport.

Although hydrophilic fibers wet more efficiently than hydrophobic fibers, they retain the absorbed water, which hinders transport.9

Stage 3: Evaporation

In the final stage of moisture management, liquid that reaches the fabric’s outer surface evaporates into the surrounding air. Under constant temperature, humidity, and airflow, the evaporation rate is governed primarily by the surface area and wettability of the fibers.10 Liquid evaporates more readily from hydrophobic fiber surfaces than from hydrophilic ones. If evaporation can’t keep pace with liquid transport to the surface, the fabric will become saturated, and the moisture will accumulate on the inner surface of the fabric, feeling wet and cold against the skin. Backpackers call this phenomenon wetting out.

Fiber Properties Affecting Moisture Management

Fiber properties that affect moisture management:

- Wettability (hydrophilicity or hydrophobicity)

- Absorption of liquid water

- Swelling

- Hygroscopicity (moisture regain)

- Fiber diameter

- Fiber cross-sectional shape

- Finishing

Wettability has already been discussed above.

Absorption of Liquid Water

Some types of fibers absorb liquid water into their internal structure. This reduces the amount of liquid available in the inter-fiber capillaries and diminishes wicking efficiency. 11

Swelling

Water absorption can cause some types of fibers to swell, narrowing or closing the capillaries and inhibiting capillary-driven liquid transport.12

Hygroscopicity and Moisture Regain

Hygroscopicity is the ability of a material to absorb and retain water vapor from the surrounding air.12

A common measure of hygroscopicity is moisture regain, defined as the percentage of water a completely dry material absorbs from the air under standard temperature and humidity conditions, expressed relative to the material’s dry weight.13

Fibers with high moisture regain can negatively affect wicking and evaporation in the same way as fibers that absorb liquid water.11

Finishing

Fabrics may be treated mechanically or chemically to to achieve properties such as smoothness, softness, water resistance, flame resistance, antimicrobial activity, or UV resistance.14 These treatments can affect moisture-wicking. In fact, some fabrics are treated specifically to enhance their moisture-wicking performance.

Fiber Diameter

Narrow fibers result in more fibers per yarn cross-section, creating smaller gaps between fibers. These narrower capillaries generate higher capillary pressure, enabling faster and longer-distance liquid transport.15,16,17

Narrow fibers also provide a larger total surface area, which enhances evaporation.

In summary, fine fibers exhibit more efficient wicking and evaporation than coarse fibers.

Fiber Cross-sectional Shape

Fibers with non-circular cross-sections or surface grooves provide additional capillary pathways and increased surface area, promoting faster liquid transport and evaporation.17,18,19,20,21,22

Moisture Management of Synthetic Fibers

Synthetic fibers are hydrophobic and have low moisture regain, allowing them to wick moisture efficiently. 14,23,24

Some manufacturers modify the structure of synthetic fibers to enhance their moisture-wicking capabilities.

Engineered Synthetic Fiber Shapes

17,28,19, 20,21,22

| Shape | Properties | Uses |

|---|---|---|

| Round | Smooth, soft, slippery, inexpensive | General use |

| Triangular | Shiny, durable, hygroscopic, breathable, bulky. | Silk-like fabrics, velveteen, decorative textiles, athletic wear |

| Trilobal , Y-shaped | Shiny, durable, hygroscopic, breathable, bulky. Scatter light to hide dirt. | Athletic wear, fashion apparel, carpets, upholstery, athletic wear |

| Four-lobed, cross, X-shaped, + shaped | High wettability, wicking, and drying. | Athletic wear, outdoor apparel, base layers, underwear, socks, quick-dry fabrics |

| Pentalobal | Very high wettability, wicking, and drying. | Athletic wear, outdoor apparel, base layers, underwear, socks, quick-dry fabrics |

| Dogbone, bowtie | Good stretch recovery, tough, strong, shiny. | Athletic knits, hosiery, intimate apparel |

| Ribbon, flat | Shiny, soft, breathable | Athletic knits, linings, fashion fabrics |

| C-shaped, crescent, kidney bean | Insulative, high moisture-wicking | Base layers |

| 4-channel, tetra-channel | Excellent wicking | High-performance athletic wear, base layers, underwear, socks, quick-dry fabrics |

| 4DG | The most effective moisture transport fiber commercially available. Excellent thermal insulation. | Extreme high-performance athletic wear, base layers, underwear, socks, quick-dry fabrics |

| Hollow round | Lightweight, excellent thermal insulation, moisture absorption, and breathability. | Insulation, sleeping bags |

| Islands-in-the-Sea | Fibers as low as 0.04 denier (about 2 microns diameter) | Synthetic suedes and synthetic leathers for for shoes, bags, upholstery. “Sea‑island fibers are commonly used in the production of high-quality textiles like sportswear, lingerie, and other apparel where softness, moisture management, and comfort are important considerations. |

| Split pie wedge | Microfibers of 0.1 to 0.2 denier | Synthetic suedes and synthetic leathers for for shoes, bags, upholstery. Not used for sportsear. |

Moisture Management of Cotton Fibers

Cotton is highly hydrophilic and has high moisture regain. When cotton absorbs sweat or other moisture, its fibers swell and close the gaps between them, further preventing the transport of moisture.32

Simply put, cotton exhibits extremely poor moisture management.

Moisture Management of Wool Fibers

A common misconception is that wool doesn’t absorb water. In fact, wool can absorb up to 35% of its weight in water, compared to 24% for cotton. 25,26,27

So why is wool considered better than cotton for moisture management?

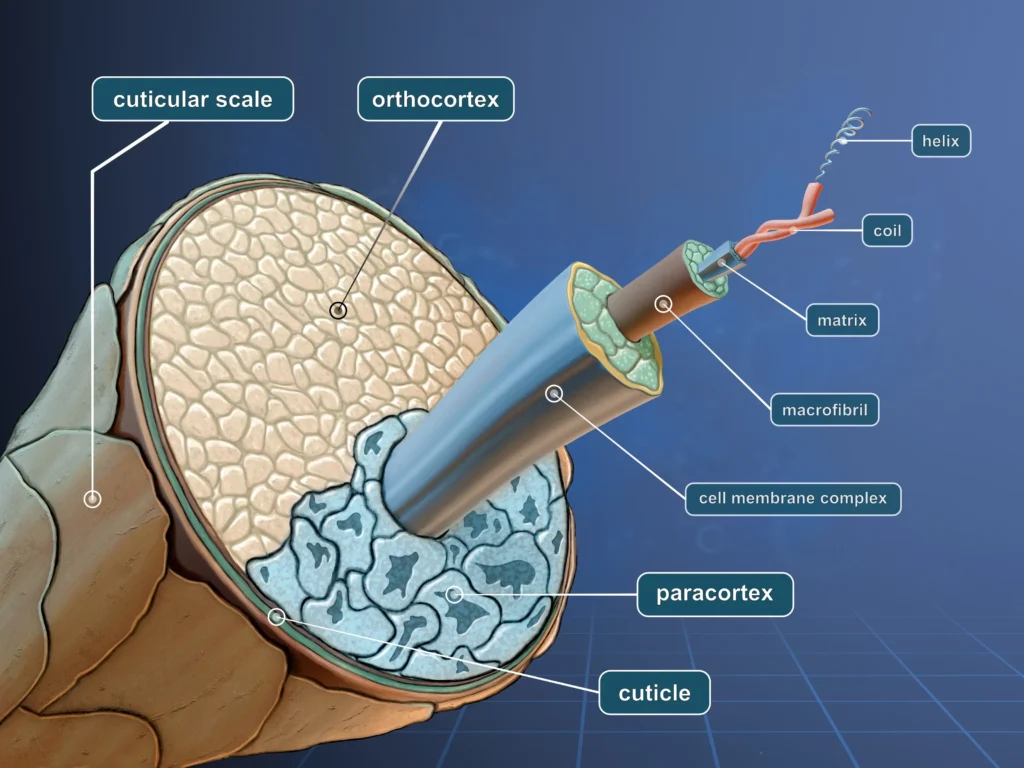

The answer lies in the dual-layer structure of wool fibers (Fig. 2):

- An inner hydrophilic core that bonds chemically with water vapor.

- An outer layer of overlapping scales, like roof shingles, with microscopic gaps between them. These scales are coated with hydrophobic lanolin.

Fig. 2

with hydrophobic shingle-like scales on its outer surface

Unlike cotton fibers, wool fibers don’t swell when wet. Instead, they flex, widening the gaps between them and promoting capillary action.

Liquid is wicked away from the skin to the fabric’s outer surface. Since the fibers’ outer layers are hydrophobic, the liquid evaporates, cooling the body during exertion or in warm weather.

Vapor, however, enters the gaps between the shingle-like scales of the fibers and bonds chemically to their inner cores (Fig. 2). The bonding reaction is exothermic—it slowly releases heat, making wet wool feel warm in cold conditions.25,26,27,28

Summary:

- Wool absorbs and holds on to water vapor but allows liquid water to evaporate

- Wool absorbs a lot of moisture before feeling wet

- Wet wool cools the body in warm conditions

- Wet wool warms the body in cold conditions

Moisture Management of Non-engineered, Finish-free Fibers

(Identical fiber weights, fiber thicknesses, yarn thicknesses, yarn twists, weave densities, and fabric thicknesses)

| Fiber | Moisture-management Performance |

|---|---|

| Polypropylene | Best |

| Polyester | Very good |

| Nylon | Good |

| Wool | Moderately good |

| Silk, bamboo viscose, hemp | Poor |

| Cotton | Worst |

Moisture Management of Weave Patterns

| Moisture Management | Weave Pattern |

|---|---|

| Moisture wicking | Satin > Twill > Plain |

| Vapor diffusion | Satin > Twill > Plain |

| Evaporation | Satin > Twill > Plain |

Waterproof/Breathable Fabrics

Waterproof/breathable fabrics such as Gore-Tex, eVent, and Neo Shell are discussed in this article:

Waterproofing

Waterproofing of clothes fabrics is also discussed in Beginner’s Guide to Rain Gear for Backpacking.

Odor Resistance

Wool is widely known to have excellent odor resistance. Wool’s odor resistance is often attributed to antibacterial properties, but this is a myth. In fact, odor-causing bacteria survive longer on wool than on polyester. Wool fibers resist odor because their keratin protein matrix obsorbs odor-causing volatile acidic and basic odor molecules, binds to them, and neutralizes them. The reaction products stay trapped in the fiber matrix and are only released whe the fabric is washed.29,30,31,32

Silk fibers are somewhat odor resistant because ther smooth surfaces resist the build-up of oily volatile compounds.33

Hemp, cotton, and bamboo viscose are also somewhat odor resistant.34

Polyester, and polypropylene have very poor odor resistance. There highly lipohilic (oil-loving) surfaces retain high levels of oil odor compounds. 35

Nylon has intermediate lipophilicity, allowing it to resist odors better than polyester and polypropylene, but not as well as wool.35

| Fiber | Odor Resistance |

|---|---|

| Wool | Best |

| Hemp | Good |

| Cotton | Good |

| Bamboo | Good |

| Nylon | Moderate |

| Polyester | Poor |

| Polypropylene | Poor |

Tenacity (Tensile Strength per Weight) of Various Fibers

| Fiber | Tenacity (g/den) |

|---|---|

| Nylon | Highest |

| Polyester | Very high |

| Polypropylene | High |

| Hemp | High |

| Silk | Medium |

| Cotton | Medium |

| Bamboo Viscose | Low |

| Wool | Lowest |

Abrasion Resistance of Various Fibers

Fibers ranked from highest to lowest abrasion resistance:

Nylon > Polypropylene > Polyethylene > Polyester > Wool > Silk > Cotton > Hemp > Viscose36

Effects of Fiber Weight, Weave/Knit Pattern, and Fabric Density on Tensile Strength, Tear Strength, and Abrasion Resistance

The effects that fiber weight, weave/knit pattern, and fabric density have on tensile strength, tear strength, and abrasion resistance are discussed in this article:

Related Topics

References

4. The Comparison of Air Permeability Among Different Textiles. March 18, 2025. Testex .

18. Pachiyappan, K. M., et al. “A Study on Fiber Size and Cross Sectional shape on Moisture Transmission Properties of knitted active sports Wear. January 2019. JETIR, vol 6, issue 1.

19. Zhang, Y., et al. “Capillary effect of hydrophobic polyester fiber bundles with noncircular cross section.” Journal of Applied Polymer Science, October 2006102(2)

27. Basuk, Shantnu, et al. Development of Double Hydrophilic/Hydrophobic Surfaces of Wool Fabric. Indian Institute of Technology Delhi.