Beginner's Guide to Fabrics for Backpacks, Tents, and Sleeping Bags

Table of Contents

Before Reading This Article ...

Fabrics Used for Backpacks, Tents, and Sleeping Bags

Nylon and polyester are the most common fabrics used for backpacks, tents, and sleeping bags.

Desirable Properties of Fabrics Used for Backpacks, Tents, and Sleeping bags

When choosing fabrics for backpacks, tents, or sleeping bags, some important properties to consider are:

- Tensile strength – The ability to resist tensile (pulling) forces before failure (breaking or stretching permanently). When expressed per weight, tensile strength is called tenacity.

- Tear strength – The ability to resist tearing (failure perpendicular to the stress being applied)

- Puncture strength – The ability to resist piercing by sharp objects

- UV resistance

- Abrasion resistance

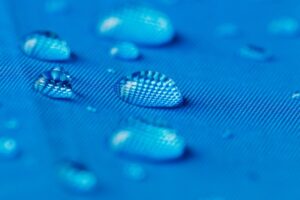

- Water resistance

- Heat resistance

- Stretch resistance

- Light weight

These properties depend on:

- Fiber type

- Fiber weight

- Weave pattern

- Weave density

Fabrics and Their Uses for Backpacks and Tents

Backpacks should be made of at least 210D ripstop nylon to prevent abrasion.

Polyester fabric is typically used for low-end tents because it’s thick and heavy to compensate for its low strength-to-weight ratio.

Most mid- to high-end tents are made of 20-40D nylon because of its high tensile strength, tear strength, and abrasion resistance. Ultralight tents are typically made of 10-20D silicone-impregnated nylon.

Dyneema Composite Fabric (DCF), also called Cuben fiber, is used in some high-end tents and backpacks because of its superior water resistance and strength-to-weight ratio. DFC consists of ultra-high-molecular-weight polyethylene (UHMWPE) coated on both sides with polyester. It’s extremely expensive.

Comparison of Polyester, Nylon, and Dyneema Composite Fabric (DCF)

| Property | Fabric Comparison |

|---|---|

| Cost | DCF > Nylon > Polyester |

| Weight | Polyester > Nylon > DCF |

| Tensile Strength | DCF > Nylon > Polyester |

| Tear Strength | DCF > Nylon > Polyester |

| Puncture Strength | DCF > Nylon > Polyester |

| UV Resistance | Polyester & DCF > Nylon |

| Abrasion Resistance | Nylon > Polyester & DCF |

| Heat Resistance | Polyester > Nylon > DCF |

| Water Resistance | DCF > Polyester > Nylon |

| Stretchiness | Nylon > Polyester > DCF |

Due to its polyester coating, DCF has UV resistance and abrasion resistance similar to those of polyester.

Effects of Fiber Weight (Denier)

Fabrics woven from fibers with high fiber weights (denier) exhibit high tensile strength, tear strength, puncture strength, and abrasion resistance. 12

Effects of Weave Patterns

Silk weaves have lower tensile strength, tear strength, puncture strength, and abrasion resistance than plain or twill weaves. 13

Effects of Weave Densities

Fabrics with higher weave densities tend to have higher tensile strength and abrasion resistance but can have lower tear strength.14

Ripstop Nylon

Ripstop nylon has strong reinforcement fibers interwoven at regular intervals in a crosshatch pattern. It’s highly resistant to tearing.

Waterproofing Coatings for Tents

Tent fabrics are typically waterproofed with one or more of the following coatings:

- Polyester urethane (PU)

- Silicone

- Polyether urethane (PE)

PU-coated fabrics are inexpensive and are commonly used for rain gear and tents. Although waterproof, they absorb water over time, making them stretchy, saggy, and susceptible to mildew. This is because PU is hydrophilic—it slowly bonds to water while preventing it from passing through.15

Silicone-impregnated fabrics have high tear strength, stretch resistance, and mold resistance, and they don’t absorb water.15 They’re also expensive. Silicone-coated nylon, or silnylon, is typically used in mid- to high-end tents.

PE is rarely used, except in high-denier floors of heavy expedition tents.15

DCF is inherently waterproof and doesn’t need to be coated.

Pros and Cons of Waterproof Coatings for Tents

| Coating | Pros | Cons |

|---|---|---|

| PU | Highly waterproof High tear strength Affordable | Absorbs water over time Stretches when wet over time Susceptible to mold |

| PE | Doesn’t absorb water Doesn’t stretch when wet Highly resistant to mold | Low tear strength Uncommon More expensive than PU |

| Silicone | High tear strength Doesn’t absorb water Doesn’t stretch when wet Highly resistant to mold | More expensive than PU |

Related Topics

References

11. Ninbo MH. Personal communication, August 19, 2025